LKH Wolfsberg is being renovated in stages as part of the action plan, which has been continuously adapted since 2012. In construction stage 3, extensive technical renovations and structural adaptations are to be carried out in the northeastern part of the hospital to create a new interdisciplinary outpatient center with adjacent dialysis.

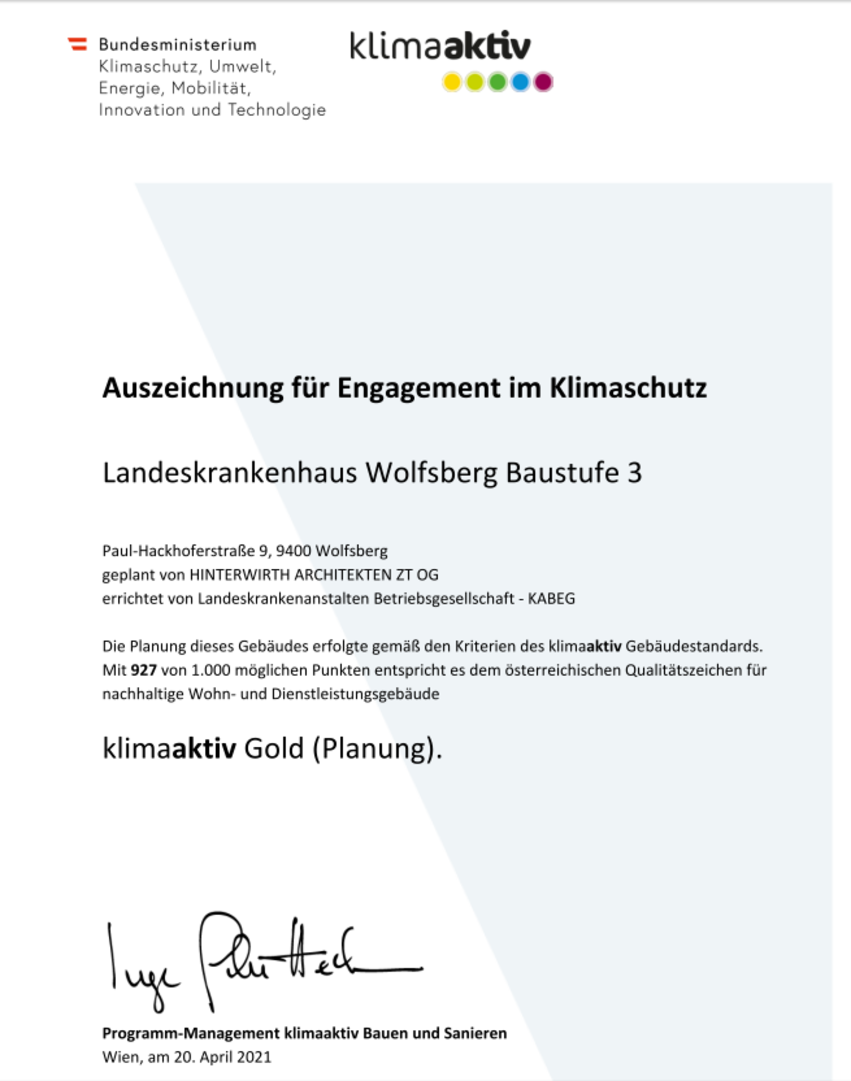

The Austrian klimaaktiv building standard demonstrates qualities of sustainable construction in this building as well. In addition to energy efficiency, the quality of planning and execution, the quality of building materials and construction, as well as key aspects relating to the comfort and indoor air quality of a building are assessed and evaluated. Only buildings that meet a particularly high quality in these areas receive awards from klimaaktiv Bauen und Sanieren.

klimaaktiv Gold in the planning assessment

The commitment of the planning team is reflected in the rating: the project achieves klimaaktiv Gold with 927 out of 1,000 possible points.

Building description

The LKH Wolfsberg is accessed by the formation of two equivalent visitor or patient entrances, both of which lead into the central entrance hall on main level 2. The northern hospital entrance is used for patient delivery to the interdisciplinary emergency outpatient clinic and is optimized by the formation of a spacious rescue hall. The partially externally operated MR Institute on the east of level 2 of building section D will be given its own operating hours, independent of the hospital, through a separate access. The oncological day clinic will be newly constructed as a one-story building with its own access.

Facade concept

The LKH Wolfsberg is a large-scale hospital complex with various building sections, parking areas, paths and streets. In order to convey a uniform overall impression, the previously realized facade concept from construction stages 1 and 2 will be taken up again for the reconstruction of the northeastern part of the hospital. Basically, the entire building section is planned with rear-ventilated aluminum cladding. There are two different color concepts here. The connecting wing, which runs from south to north through the entire hospital, will be visually extended in levels 3, 4 and 5. This part of the building will be finished in light gray with anthracite aluminum window bands. The parts of the building branching off from the connecting wing (dialysis, emergency, ZRI, oncology and themed outpatient clinic) will be white with aluminum window bands that match the color of the wood window bands from the existing building. In this area, the canopies will also form a horizontal line, as in the existing G and I components.

Building services

Heat will be supplied from the local district heating network via a new heating converter station to be built in the technical area. Each consumer group (ventilation systems u. static heating circuits) can be operated depending on the outside temperature and the special requirements of the respective supply area. The local heating system ensures the room temperatures in winter in the individual rooms independently of the operation of the ventilation systems. As a rule, underfloor heating systems are provided for heating the individual rooms.

The hot water supply will be provided by a new hot water preparation system to be installed on level 1. The system will be designed in compliance with ÖN B 5019 using the instantaneous water heater principle, with hot water storage tanks being used for peak flow coverage. The system components will be designed redundantly. This system will supply the building components of construction stage 3 and building C (surgery bed wing). The medical bed wing will also be supplied until it is demolished.

The task of the ventilation and air-conditioning systems is to create a room climate in the respective areas of use that complies with user requirements, the currently recognized rules of technology and the laws and regulations. The main tasks are:

- ensuring the supply of fresh air

- he removal of pollutant-containing, odor-contaminated room air

- heating, cooling, humidifying and dehumidifying to defined room air conditions.

Full air-conditioning systems and ventilation systems are used as ventilation systems. Steam is generated decentrally by means of electric steam humidifiers. The GLT is the central monitoring and control of the technical systems. The basic functions are monitoring, remote control and data recording of the heating, ventilation, air conditioning and sanitary systems (HVAC - systems). They are to be seen as a superordinate unit to the DDC. The HVAC systems are controlled and regulated by freely programmable control systems (DDC systems). The control systems are coordinated with the building services systems and are an automation unit for monitoring, controlling, regulating and optimizing the HVAC systems.

A new refrigeration system will be installed to supply the room air conditioners with cold. This is planned with a heat pump function so that part of the heat requirement can be covered during the heating season. The cooling supply in winter (MRT, CT) will be ensured by a separate small refrigeration plant, the waste heat will be used for air preheating.

Construction product management

The IBO also accompanies the project in the execution phase: a comprehensive building product management is carried out according to the criteria of klimaaktiv. The building materials are checked for compliance with HFC-free insulating materials, assembly foams, the avoidance of PVC in foils, windows/doors/gates and sun protection. In addition, preference is to be given to products with eco-labels that take into account the entire life cycle of a product. Furthermore, the materials should be low in emissions and pollutants. The criteria were added to the tenders, and the tenders were reviewed. During the construction process, the products used are approved, and if they do not meet the criteria, alternatives are sought. On the construction site, random checks are carried out to ensure that the carefully selected building products are actually being used. Final room air tests show whether the desired quality level has actually been achieved.

Particularly in hospitals, where weakened people spend around the clock indoors, indoor air quality is of special importance for recovery, but also for the health of the staff. Especially for surfaces such as floor coverings or wall protection, the combination of ecological requirements with strict hygiene regulations is particularly challenging.

After the planning declaration was successfully completed, the IBO will continue to accompany the construction project until its completion in 2023.